The Only Guide to PEEK 450G DATA SHEET

PEEK Technical Data Sheets - MatWeb Things To Know Before You Get This

Polyetheretherketone (PEEK) is a high-performance thermoplastic material that is an. It and is. Click Here For Additional Info can be utilized continually in operating temperature levels up to 480 F and in hot water or steam without any compromise to its physical residential or commercial properties. PEEK provides wear, moisture and chemical resistance in addition to exceptional strength, dimensional stability and stiffness.

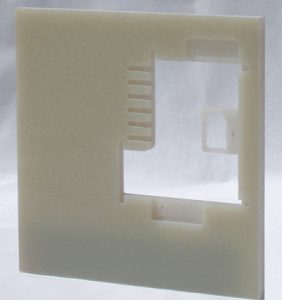

PEEK is quickly machined. Call 800-367-9122 or email PEEK Product Residence Offered By Dielectric Production, Richfield, Wisconsin.

What Is PEEK Plastic? PEEK plastic, also referred to as polyetheretherketone, is perfect for parts utilized in severe environments that require excellent chemical resistance over a broad variety of temperatures. PEEK is crafted resin designed to perform well applications that require and hydrolysis resistance while maintaining stiffness with PEEK temperature limits up to 170C/ 338F.

Some Known Details About PEEK- UNFILLED (POLYETHERETHERKETONE) - Sterling

Chemical resistant Hydrolysis resistant Radiation resistant Autoclavable, resistant when exposed to boiling water and direct exposure to hot steam Fatigue and stress-crack resistant Creep resistant Low wetness absorption Low coefficient of direct thermal expansion Stable at raised temperature levels up to 170C/ 338F UL 94 V-0 flammability rating Low poisonous gas and smoke emissions Lightweight and chemically inert Dimensionally steady Controlled porosity Look white to off-white/natural Easy to make and machine PEEK Plastic Properties PEEK tensile strength psi D638 14,000 24,620 PEEK flexural modulus psi D790 590,000 1,450,000 PEEK Izod effect (notched) ft-lbs/in of notch D256 1.

84 PEEK heat deflection temperature @ 264 psi F D648 306 599 Optimum constant servicetemperature in air F 480 482 Water absorption( immersion 24 hr) % D570 0. 50 0. 11 PEEK coefficient of linear thermal expansion in/in/Fx10 -5 D696 2. 6 1. 2 PEEK coefficient of friction (dynamic) 0. 25 0. 30 ** Values might vary by PEEK product brand/ molding conditions.

PEEK Product Applications PEEK offers unique homes making it an ideal solution over a wide variety of applications that require high-temperature, chemical, UL rating, stiff, hard and creep resistant materials. Nuclear Oil and Gas Medical & Pharmaceutical Aerospace Semiconductor Food Processing Filter Manufacturing Equipment and equipment components Rings and seals Bushings and bearings Instrument parts Down hole electrical components Biodiesel filters Grades of PEEK Plastic Naturally abrasion resistant, unfilled, virgin PEEK product provides wear and steam resistance.

UNDER MAINTENANCE